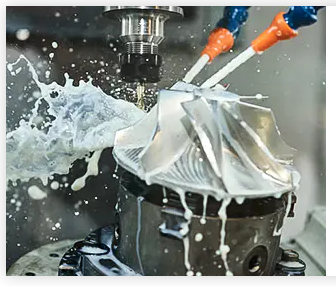

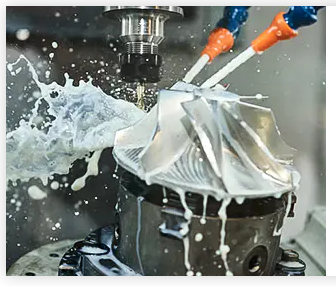

Precision CNC (Computer Numerical Control) machining is a manufacturing process that uses computer-controlled machines to create highly accurate and complex parts and components. In this process, a computer program is used to control the movement of machine tools, such as lathes, mills, and routers, to cut and shape raw materials, such as metal, plastic, or wood, into a precise and intricate design.

CNC machines are capable of producing parts with very high accuracy and consistency, making them ideal for applications that require tight tolerances, intricate geometries, or complex shapes. The precision of CNC machining is achieved through a combination of computer control, specialized cutting tools, and high-quality materials.

Precision CNC machining is used in a wide range of industries, including aerospace, automotive, medical, and electronics, where high-quality and reliable parts are critical to the performance and safety of the end product.

Precision CNC (Computer Numerical Control) machining is a manufacturing process that uses computerized machines to accurately and efficiently produce complex parts and components. Some of the characteristics of precision CNC machining include:

High accuracy: CNC machines are capable of achieving high levels of precision and accuracy, often down to fractions of a millimeter or even microns. This ensures that parts and components are manufactured to exact specifications and are consistent in size and shape.

Repetitive accuracy: Once a CNC machine is programmed, it can produce identical parts repeatedly and reliably, ensuring consistent quality and reducing the risk of errors or defects.

Flexibility: CNC machines can be programmed to produce a wide range of parts and components, making them ideal for manufacturing complex parts with intricate geometries.

Efficiency: CNC machines can perform operations quickly and efficiently, reducing the time and labor required to manufacture parts and components.

Automation: CNC machines can be fully automated, allowing them to operate around the clock without human intervention. This improves productivity and reduces labor costs.

Quality control: CNC machines can be equipped with sensors and monitoring systems to ensure that parts and components meet quality standards. This reduces the risk of defects and improves overall product quality.