In the dynamic arena of modern manufacturing and precision engineering, the mastery of materials stands as a defining pillar of innovation. The exploration of custom CNC milling techniques has propelled the realm of craftsmanship to unparalleled heights, ushering in an era where raw materials are not merely shaped but transformed with a degree of precision and creativity that knows no bounds. Far transcending conventional manufacturing processes, these techniques hold the key to a realm of infinite possibilities. They enable the metamorphosis of raw materials into intricately designed and custom-crafted components, a transformation that shatters the limits of both precision and artistry.

Custom CNC milling techniques are a true testament to the symphony that emerges when technology and ingenuity unite. Unlike traditional machining methods, which may falter when confronted with intricate designs, custom CNC milling is a marvel of precision. This intricate dance between a computer numerical control (CNC) system and a milling tool orchestrates a process where materials are sculpted with meticulous accuracy. The result is an array of shapes and forms that adhere rigorously to exacting dimensions and tolerances.

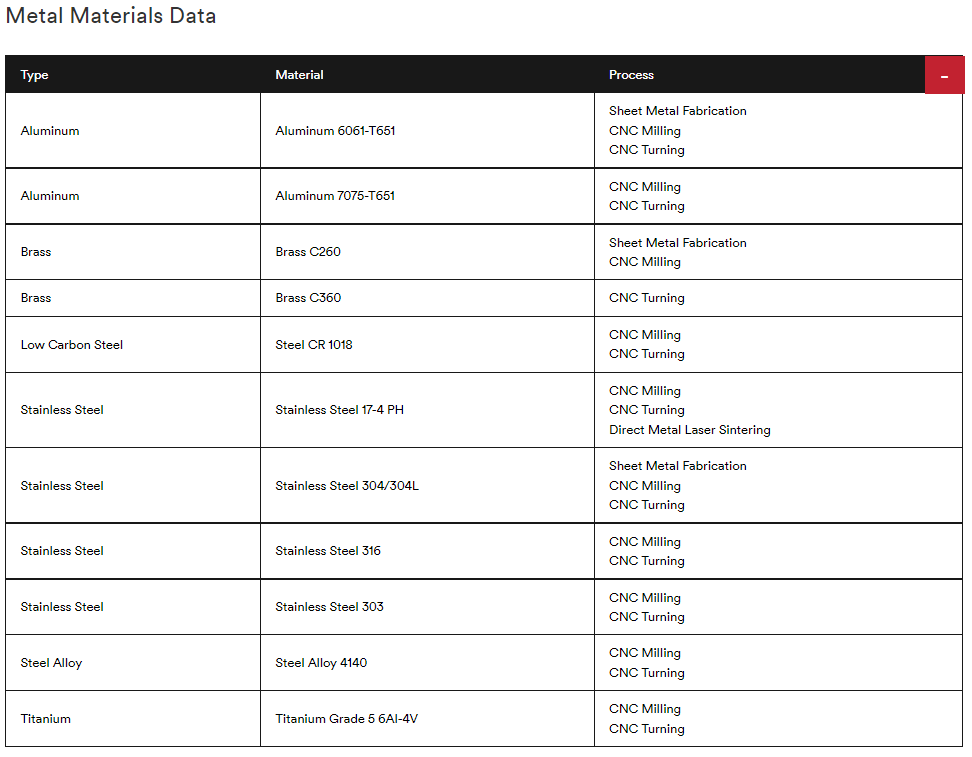

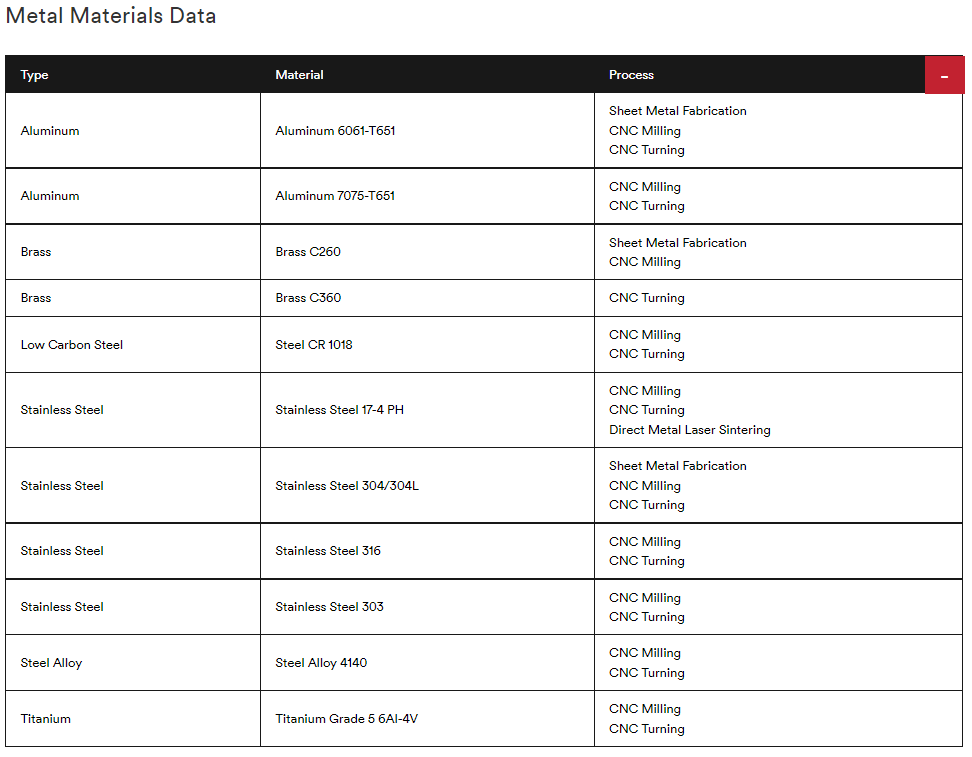

A hallmark of custom CNC milling techniques is their exceptional ability to unlock the realm of creative possibilities by shaping an extensive array of materials. From sturdy metals like aluminum and steel to advanced composites and versatile plastics, these techniques possess the remarkable ability to engage with a spectrum of materials. This inherent versatility empowers manufacturers, designers, and artists to embark on journeys of innovation, converting raw materials into both artistic expressions and functional components that flawlessly blend aesthetics with utility.

At the heart of custom CNC milling lies a revolution in the art of customization. Designers and manufacturers wield the power to stretch the boundaries of imagination by crafting designs that align with specific needs. Whether it involves crafting intricate patterns, complex geometries, or even bringing one-of-a-kind prototypes to life, custom CNC milling techniques excel at turning conceptual visions into tangible realities. This revolution of customization paves the way for the creation of components that embody individuality and purpose, satisfying the unique requirements of a multitude of industries.

The confluence of precision and consistency sets custom CNC milling techniques on a pedestal of their own. The orchestration of these techniques ensures that each component, regardless of complexity, is fashioned with unwavering precision. Once the design is transcribed into the CNC system, the milling process unfailingly reproduces the same outcome with pinpoint accuracy. This exceptional level of consistency eradicates any potential for variability, resulting in components that seamlessly integrate within the broader framework of manufacturing and assembly.