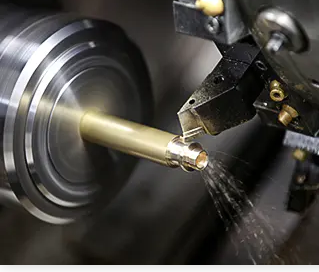

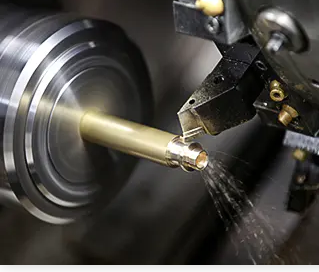

CNC turning is a manufacturing process used to create cylindrical parts by removing material from a rotating workpiece using cutting tools that are applied to the workpiece in a linear motion. The process is carried out using a computer-controlled machine tool called a CNC lathe, which is specifically designed for turning operations.

CNC turning is a highly accurate and precise process that can be used to produce parts with complex geometries and tight tolerances. The process is also known for its efficiency and speed, allowing for high-volume production of parts with consistent quality.

The CNC turning process involves the following steps:

Preparation: The first step is to prepare the workpiece for machining. This involves securing the workpiece to the lathe chuck, which is a device that holds the workpiece in place as it rotates.

Tool selection: The next step is to select the appropriate cutting tools for the job. The cutting tools used in CNC turning are typically made from high-speed steel or carbide and come in a range of sizes and shapes to accommodate different types of cuts and materials.

Programming: Once the workpiece is secured and the cutting tools are selected, the operator programs the CNC lathe with instructions for the cutting tools to follow. This is typically done using computer-aided design (CAD) software that generates a set of tool paths for the cutting tools to follow.

Machining: With the programming complete, the CNC lathe begins the machining process. The cutting tools are applied to the workpiece in a linear motion, removing material and creating the desired shape and surface finish.

Finishing: Once the machining is complete, the part is removed from the lathe and any necessary finishing operations, such as deburring or polishing, are carried out.

CNC turning can be used to produce a wide range of parts, including shafts, bearings, bolts, and screws, as well as more complex components such as aerospace and medical parts. CNC turning is widely used in manufacturing and engineering industries for its ability to produce parts with high accuracy, consistency, and efficiency.