CNC Machining is the use of CNC machine tools to process metals, etc., and also refers to the processing of CNC machining tools. CNC index-controlled machine tools are programmed and controlled by CNC machining language, usually G code. The CNC machining G code language tells the CNC machine tool which Cartesian position coordinates to use for the machining tool, and controls the tool feed rate and spindle speed, as well as tool changer, coolant and other functions. CNC machining has great advantages over manual machining. For example, the parts produced by CNC machining are very accurate and repeatable; CNC machining can produce parts with complex shapes that cannot be completed by manual machining. CNC machining technology has been widely promoted, and most machining workshops have CNC machining capabilities. The most common CNC machining methods in typical machining workshops are CNC milling, CNC turning and CNC EDM wire cutting (Wire EDM). The tools for CNC milling are called CNC milling machines or CNC machining centers. A lathe that performs CNC turning is called a CNC turning center. CNC machining G codes can be programmed manually, but usually machine shops use CAM (Computer Aided Manufacturing) software to automatically read CAD (Computer Aided Design) files and generate G code programs to control CNC machine tools. Leading CNC machine brands are Hass, DMG (Deckel Maho Gildemeister), Mazak, Mori Seiki, Fadal and Wasino.

| Custom CNC Machining Parts | |

| Materials Available- Plastic | ABS /PC /PP /POM /PE ect... |

| Materials Available- Metal | aluminum/ stainless steel /steel / brass ect... |

| Surface Treatment | polishing /anodizing / painting ect... |

| Processing | CNC Turning, Milling parts, Drilling, Auto Lathe, Tapping, Bushing, Surface Treatment, etc. |

| Drawing Formats | > SolidWorks (.sldprt)> ProE (.prt)> IGES (.igs)> STEP (.stp)> Parasolid (.x_t)> .stl |

| Tolerance丨Surface Roughness | +/-0.005 - 0.01mm 丨 Ra0.2 - Ra3.2(Customize Available) |

CNC MACHINING - PLASTIC

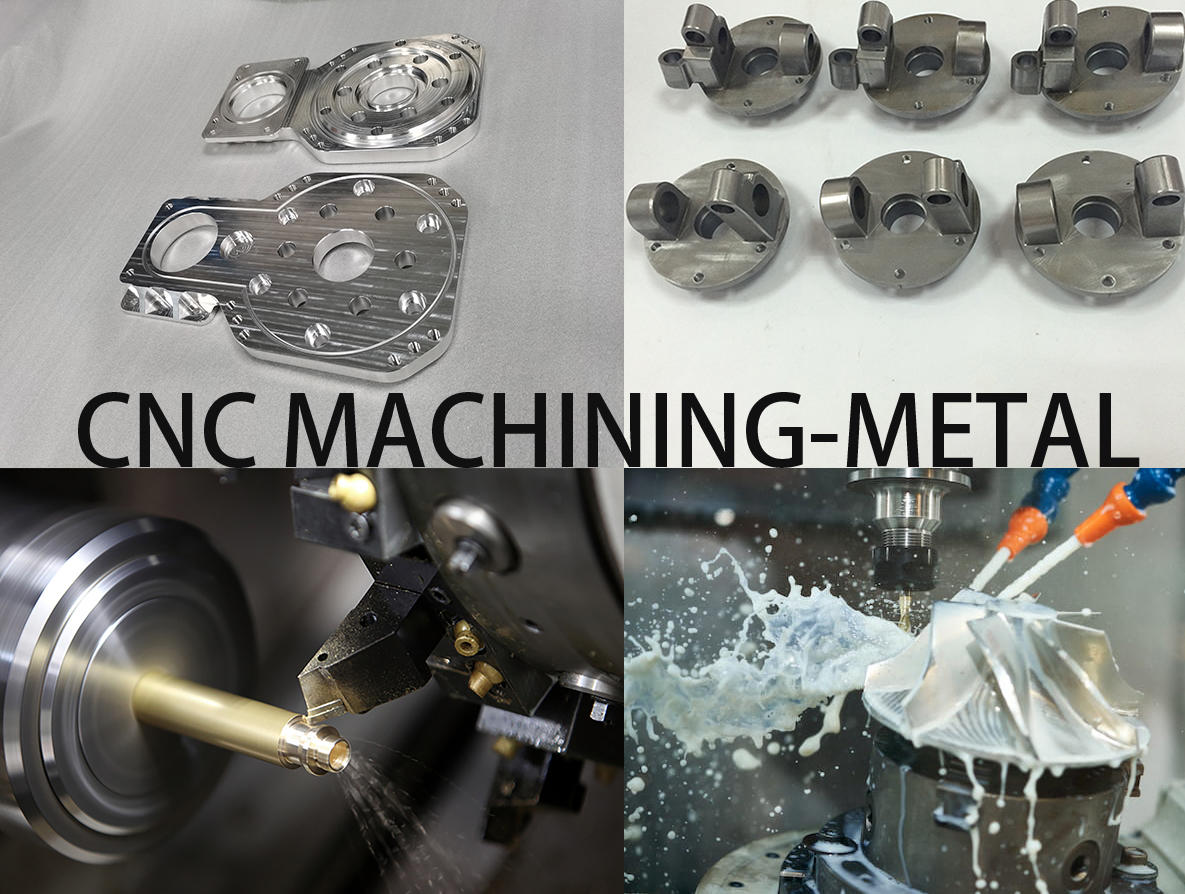

CNC MACHINING- METAL

5 axis /3 axis

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

FAQ

Q1:What format files do you need for quotation?

Rongna: IGES (.igs) /STEP (.stp) /Parasolid (.x_t) / .stl files.

Q2: Can we sign NDA?

Rongna: Sure. We never divulge customers' information to anyone else.

Q3: What's MOQ ?

Rongna : 1 pcs , we provide prototype to mass production service

Q4: How can you ensure the quality?

Rongna : We have profesional QC department to guarantee the quality.

Q5: Delivery time?

Rongna: Prototype can finish as fast as 1 day ! depends on your quantity .

Q6: How about the transportation?

Rongna : Express ( Fedex /UPS /TNT ), Sea Shipping , air Shipping

Custom CNC Machining Factory

Custom CNC Machining Factory

we help client Develop New Products, form Sample to mass Production.